Our Process

Crafting Brilliance, Step by Step

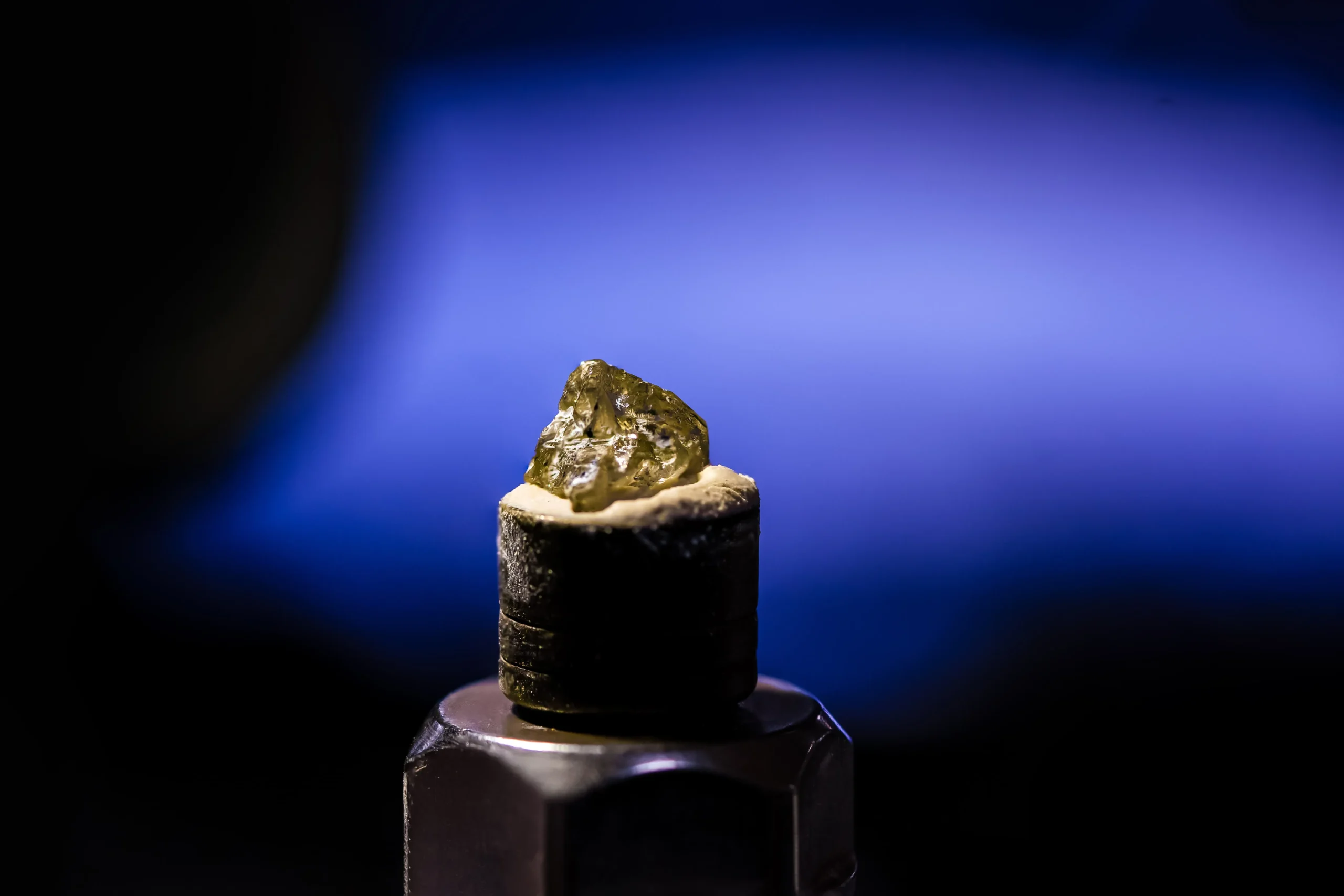

1️⃣ Rough Assortment

Once rough diamonds are sourced responsibly, our skilled experts sort them by size, shape, clarity, and potential. This initial sorting is crucial to determine how each stone can be maximized for its natural beauty.

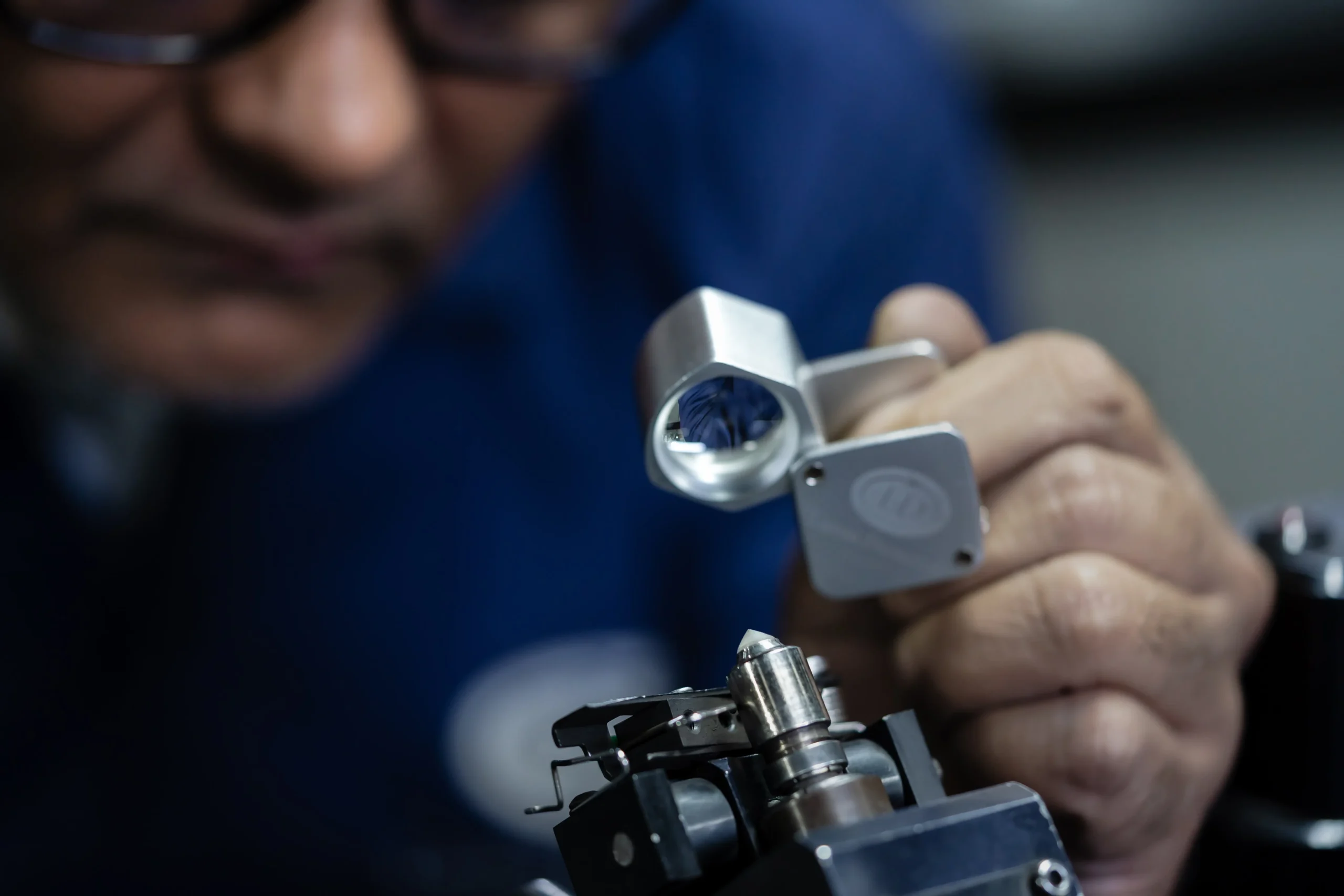

2️⃣ Diamond Cleaving & Marking

Using precision tools and in-depth analysis, we mark and cleave the rough diamonds to separate them into workable segments. This step requires both scientific accuracy and intuitive craftsmanship to ensure minimal wastage.

3️⃣ Laser Sawing

With the help of state-of-the-art laser technology, diamonds are precisely sawn into smaller parts based on the initial cleaving. This modern method ensures clean cuts with minimal loss, preserving the value of each stone.

4️⃣ Cutting & Polishing

This is where raw brilliance is transformed. Our master cutters shape each diamond into its final form — whether round, princess, emerald, or custom cuts. The polishers then enhance the stone’s fire, brilliance, and symmetry.

5️⃣ Assortment & Grading

Finally, each finished diamond is carefully graded and sorted by our experts and certified by reputed gemological laboratories. This ensures consistent quality and complete transparency for our clients worldwide.